What materials are used in an MRI?

In an MRI (Magnetic Resonance Imaging) machine, several materials are used:

Superconducting Magnets: The primary component of an MRI machine is the superconducting magnet, typically made from niobium-titanium or niobium-tin alloys cooled to extremely low temperatures using liquid helium.

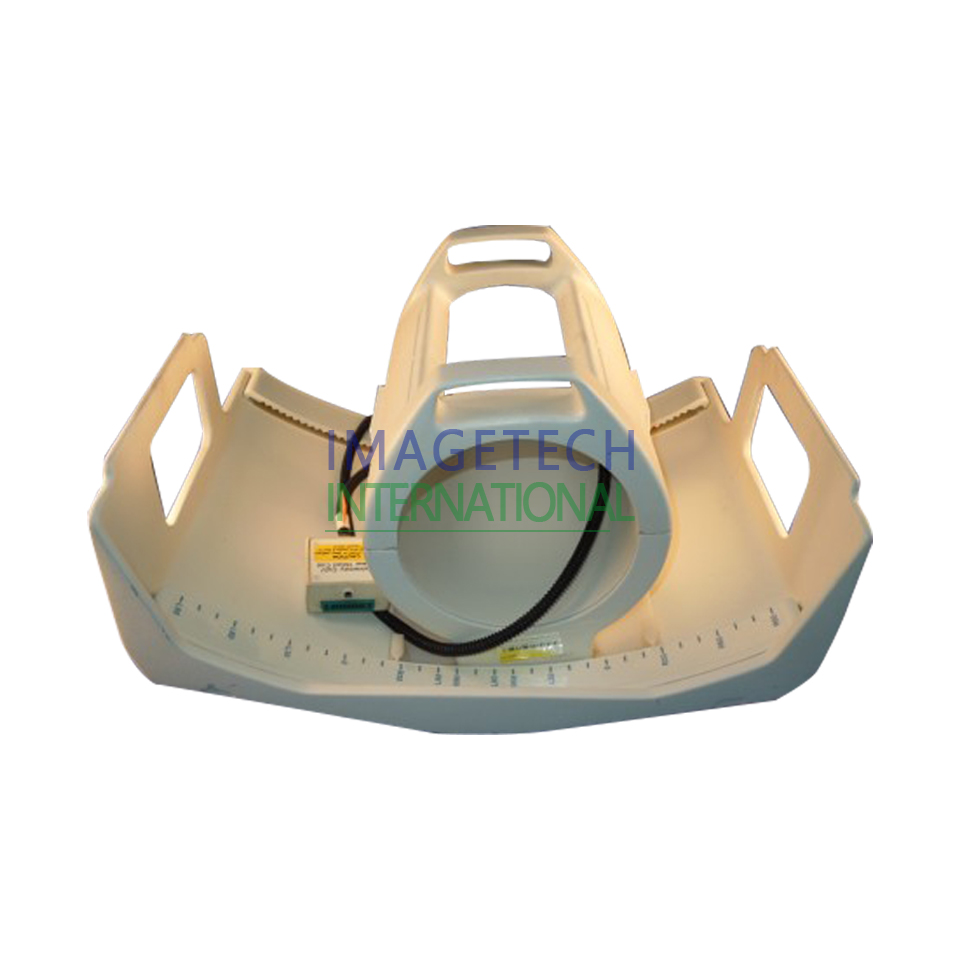

Gradient Coils: These coils produce the varying magnetic fields necessary for spatial encoding in MRI images. They are usually made of copper wire.

Radiofrequency (RF) Coils: RF coils are used to transmit radiofrequency pulses and receive signals from the body. They are typically made from copper or other conductive materials.

Shimming Coils: These coils are used to fine-tune the magnetic field homogeneity within the MRI scanner. They are also made from conductive materials like copper.

Shielding Materials: MRI machines are shielded to prevent external electromagnetic interference from affecting image quality. This shielding is typically made from materials like steel or copper.

Patient Table and Housing: The patient table and housing of the MRI machine are usually constructed from non-magnetic materials such as plastic, fiberglass, or aluminum.

Coolants: Liquid helium is commonly used to cool the superconducting magnets to their operating temperature, typically around 4 Kelvin (-269°C). Liquid nitrogen may also be used for cooling certain components.

Electronic Components: Various electronic components, such as amplifiers, filters, and processors, are used to control and process the signals generated by the MRI machine. These components typically contain metals like copper, silicon, and various semiconductors.

These materials work together to generate, manipulate, and detect the magnetic fields and radiofrequency signals necessary for imaging the human body in an MRI machine.

Neil

Neil

Neil

Neil